This is an old revision of the document!

Labview

LabView implementations have been created by the Hari Shroff lab and used by collaborators. Contact them directly for LabView code (also available on wormguides.org but probably out of date).

In general LabView is recommended only for groups doing significant custom software development within an existing LabView framework. End users are probably better off using Micro-Manager or a commercial software. Micro-manager is open-source and extensible so it can also be utilized by groups doing custom software development.

LabVIEW (LV) Tutorial:

Overview This tutorial provides an outline of the front panel controls of two LabVIEW (LV) programs developed by the Shroff lab at the NIH to control new functionality in diSPIM1,2: stage-scanning and slit-scanning (see also the MBL Biological Bulletin article). Here we describe in detail the role of each control on the front panel. Section A shows exemplary waveforms given to the hardware in order to provide stage- and slit-scanning functionality. The Stage-scan LV program (section B) controls the hardware to acquire images in stage scanning mode, where the sample is scanned through the waist of a stationary light-sheet. The same program is modified to additionally provide slit-scanning functionality (section C), whereby the width of the camera rolling shutters can be controlled to achieve confocality in the laser beam scan direction (‘y’). Finally, section D provides some example images illustrating how to empirically set the slit-scan parameters, when using a dye solution. We previously described a similar program for controlling diSPIM in ‘conventional’ image acquisition mode (synchronously sweeping the light sheet and detection focal plane through the sample)2; the LV programs described below use the same hardware. For feedback or queries please contact Abhishek Kumar (abhishk@gmail.com) or Hari Shroff (drbar314@gmail.com).

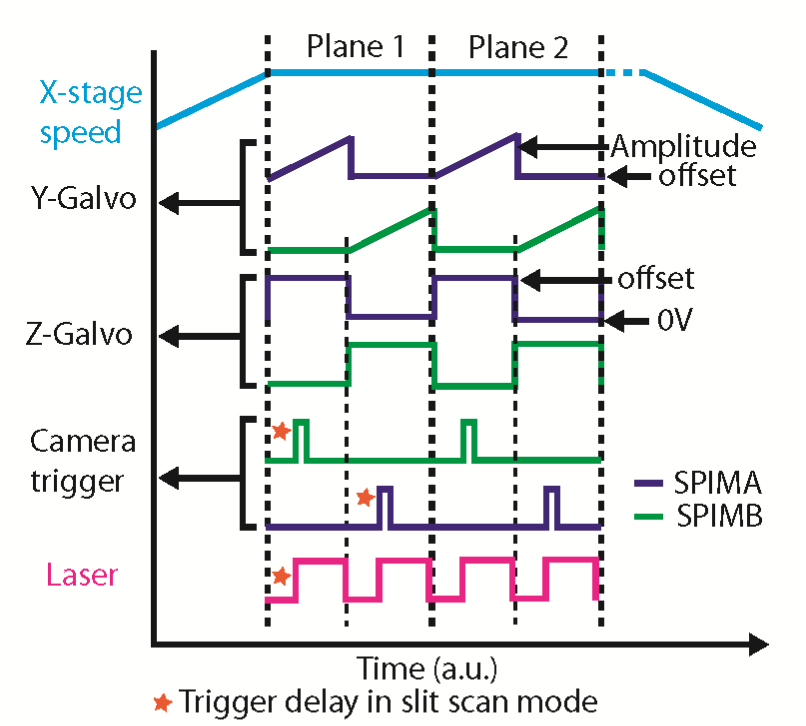

A. Schematic of example waveforms provided to the diSPIM for hardware control: Waveforms are generated by the DAQ and provided to the various diSPIM hardware components. See the MBL Biological Bulletin paper for more information.

The ‘Y-Galvo Amplitude’, ‘Y-Galvo offset’, and ‘Camera Trigger delay’ are referred to again in Section D.

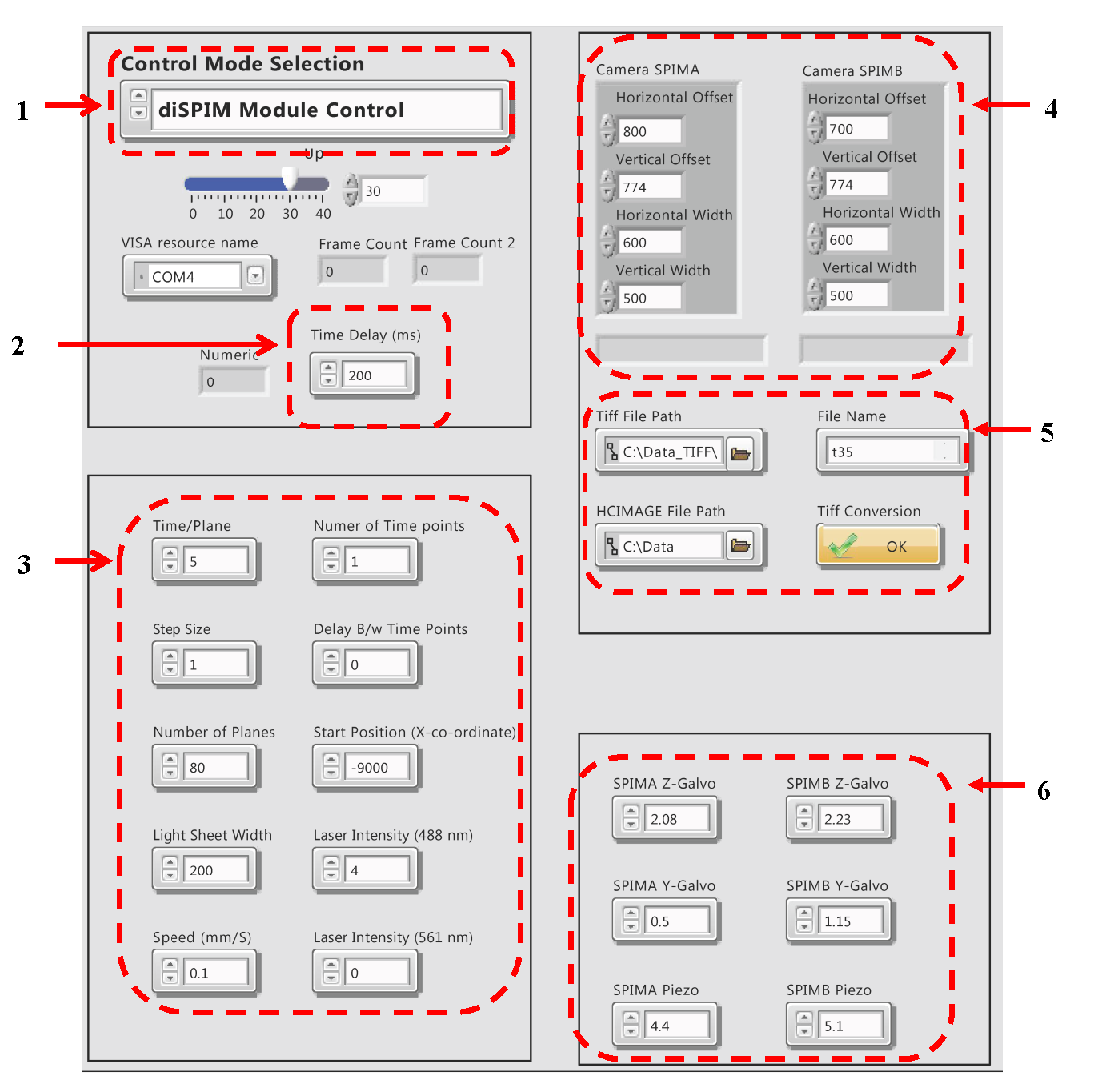

B. Stage-scan LV front panel details:

1. Control Mode Selection: Select from different modes: DiSPIM Module: Used to move the diSPIM module housing the two diSPIM objectives. User can define the distance (in mm) and LV provides a serial command to the TIGER Controller, moving the LS-50 motorized stage to the specified position. GFP Image Acquisition: Selected when single color, GFP- or similar fluorophore (excitation by 488 nm laser) is imaged. Images are acquired for both views, plane by plane. The stage starts moving with constant speed and images are acquired while the sample is being translated. mCherry Image Acquisition: Same as previous mode, but used for mCherry or similar fluorophore (excitation by 561 nm laser). Dual Color Image Acquisition: This mode is used for imaging both channels. In this mode, the two views are alternately acquired plane by plane, and at each plane, images for each color are alternately acquired. Parameter Adjustment: This mode controls the MEMS mirrors and objective piezos. It is useful for parameter optimization or alignment. Camera, laser and stage control are not supported in this mode.

2. Time Delay: Extra, ‘pre-acquisition’ time delay is provided to the X-stage for acceleration. This way, when image acquisition starts, the stage is moving with a constant speed. A typical value is 10 um.

3. Various Imaging Parameters:

Time/Plane: For 500×500 pixels region of interest (ROI), the minimum is 5 ms. Step size: in um # of Planes: i.e. the number of planes per volume Lightsheet width: In um, and depends on the camera ROI. Speed: Defines the speed of motorized stage and is dependent on the timing and step size. We typically use 0.1 mm/s for single color, 1 um z’ step size (equivalent to 0.7 um z step size). Number of time points: The number of volumetric time points in the image acquisition. Delay b/w time points: In seconds Start Position: The X-coordinate of the sample being imaged. Once the sample is positioned using the bottom camera, the X-coordinate of the stage can be determined. Laser Intensity (488 nm): arbitrary units Laser Intensity (561 nm): arbitrary units

4. Camera ROI Settings: Set ROI depending on sample size being imaged.

5. File Path and File Name: The LV Program saves the acquired images in HCIMAGE format (Hamamatsu proprietary format) and then converts the data into TIFF format. The file path for both formats needs to be provided. LV creates sub directories named SPIMA and SPIMB in the parent directory. TIFF conversion can be performed during acquisition or after, using the TIFF conversion sub VI. The file name needs to be changed for each run. For time series, the file name is appended with the time point number.

6. Galvo and Piezo Offsets: SPIMA & B Z-galvo: Used to position the lightsheet so that it is well synchronized with the detection piezo. Voltage can be set between 0-4 V. SPIMA & B Y-galvo: Defines the laser scan start position on the camera ROI (range 0-4 V). SPIMA & B Piezo: Used to position the imaging objective and excitation beam at the appropriate position (range 0-10 V).

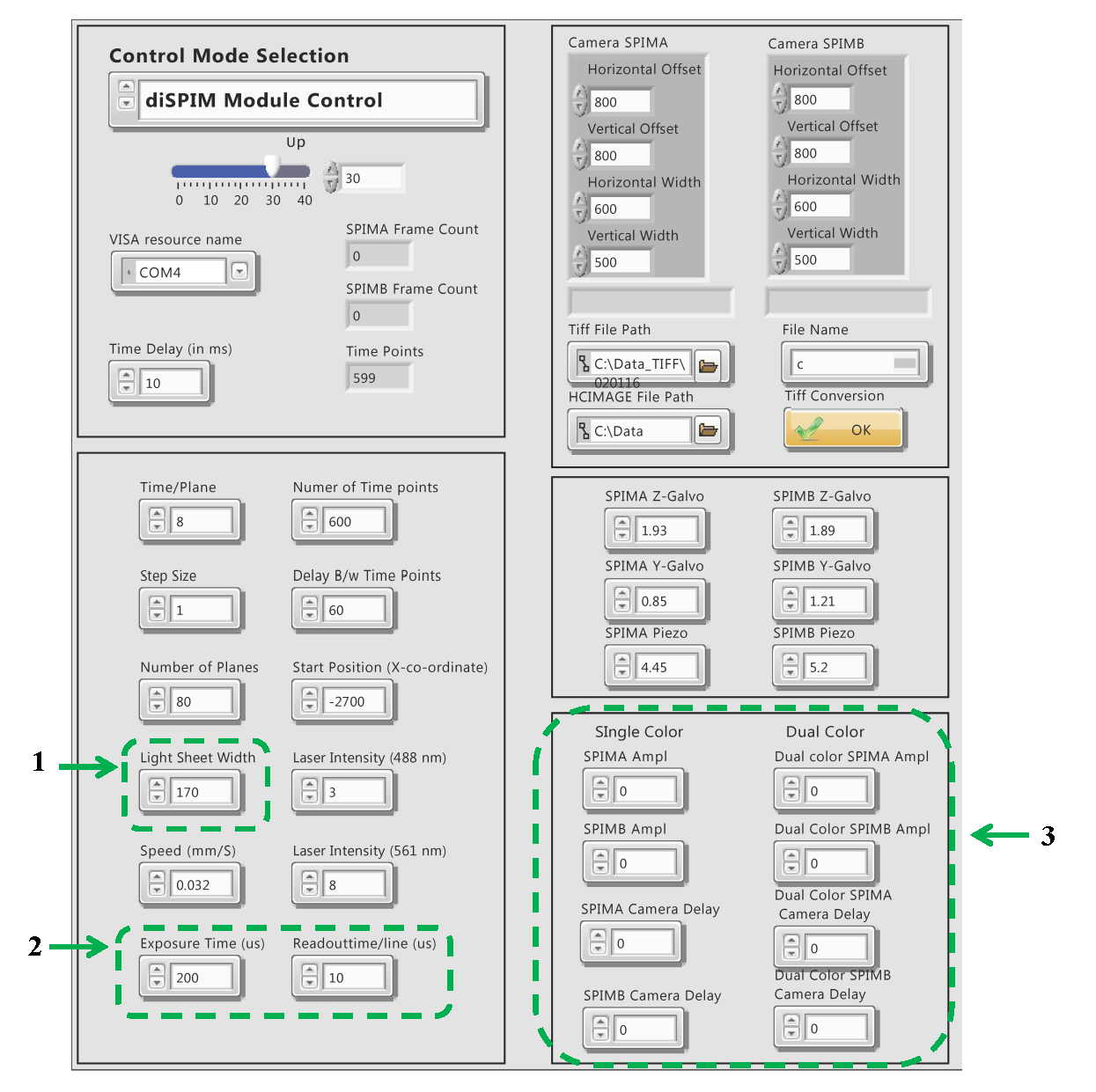

C. Stage-scan with Slit-scan LV front panel details: All controls in this mode are the same as described above, except the three regions marked in green.

1. Light Sheet Width: Set to zero in this mode.

2. Exposure Time (us): A user defined parameter for slit scan. Please look at the Hamamatsu Flash 4.0 V2 camera manual for more details about lightsheet mode, ROI, readout direction and timing information. Readout Time (us): The readout time of a column of pixels for the Flash 4.0 Hamamatsu camera. This can be set in multiples of 10 us. Slit width is defined as the exposure time divided by the readout time.

3. SPIMA and B Amplitude for Single and Dual Color: This control is given to set the amplitude of each arm individually. This is a critical parameter for proper synchronization of rolling shutter with the laser scan (y-scan). SPIMA and B Camera Delay: This sets the camera trigger delay with respect to the Y-galvo scan. This is in % of total time per plane for two views. Typical values are ~2.4-3.2 ms delay assuming 8 ms/plane for each view. This is ~15-20 % delay of the total time/plane (16 ms) for two views.

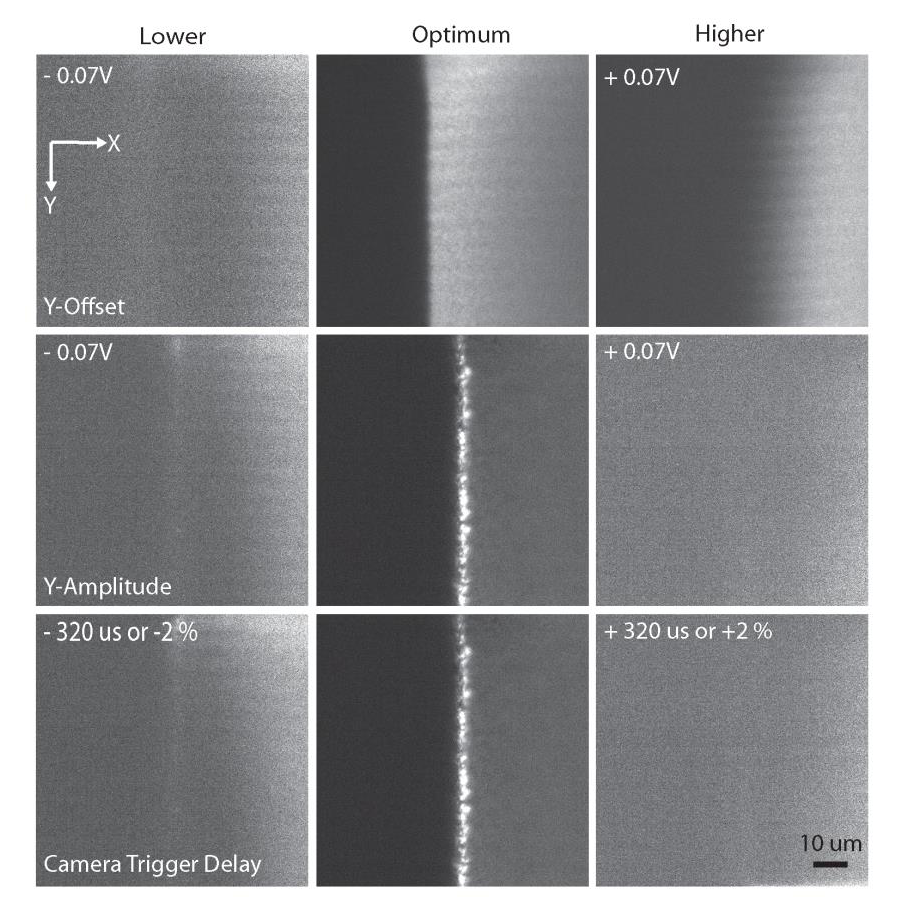

D. Examples showing the effect of Y-offset, Y-Amplitude and Camera Trigger Delay in slit scan mode.

See also the waveform schematic in section A. Parameters are optimized using dye solution (here, fluorescein). The bright line in the center (see images below) is the edge of the coverslip, the right side of each image shows the dye above the coverslip, and the left side shows the region below the coverslip. At optimum parameter settings, the laser paints the pixels uniformly. Small deviations from the optimum parameter values can significantly affect the quality of imaging. Top row shows the effect of changing the Y-galvo offset. Changing the offset value (+/-) 0.07 V from the optimum, results in a rolling shutter readout that is completely out of sync with the laser scan, and fluorescence signal and uniformity is much reduced. Changing the amplitude (middle row) by .07 V also adversely affects the synchronization (middle row). Similarly, small changes in the camera trigger delay offset also adversely affect synchronization (bottom row).